How do you make nylon cable ties?

1.Material Preparation:

Nylon pellets or other plastic materials are loaded into hoppers and supplied to the injection molding machine through an automated feeding system.

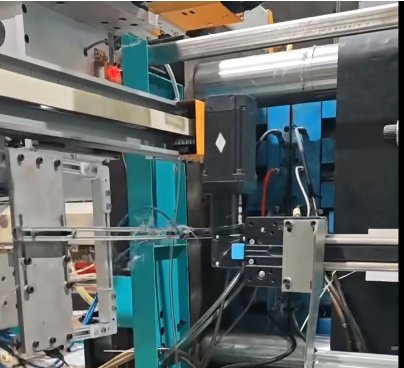

2.Injection Molding:

The injection molding machine injects heated plastic material into the mold, which shapes the nylon cable ties as required.

3.Cooling and Solidification:

The molded nylon cable ties are cooled and solidified using a cooling system, ensuring they harden and maintain their shape.

4.Demolding and Cutting:

The cooled nylon cable ties are removed from the mold and cut to the desired lengths using automated cutting equipment.

5.Quality Inspection:

The cut nylon cable ties undergo quality inspection, including visual checks, dimensional measurements, and strength testing, to ensure they meet product standards.

6.Packaging:

Qualified nylon cable ties are packaged using automated packaging lines according to customer requirements and labeling standards.

7.Finished Product Storage:

Packaged nylon cable ties are transported to the finished product warehouse via automated conveyor systems, ready for shipment or delivery to customers.

Advantages of Automation:

Improved Efficiency: Automation reduces manual labor and streamlines production processes, leading to higher productivity and faster turnaround times.

Consistency: Automated production ensures consistent quality and precision, minimizing variations and defects in the finished products.

Cost Savings: By reducing labor costs and minimizing errors, automation can lead to overall cost savings in production.

Increased Safety: Automation eliminates many manual tasks, reducing the risk of workplace accidents and injuries.

Scalability: Automated production systems can be easily scaled up or down to meet changing demand, providing flexibility in production capacity.

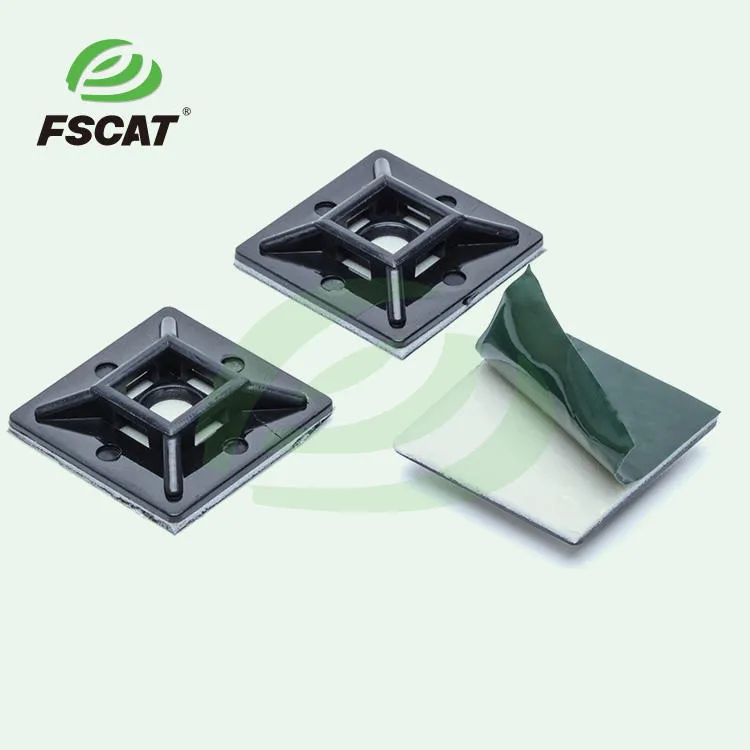

Why Choose Fscat Cable Ties?

1.Better Molds, Thicker Ties: Our cable ties are produced with superior molds and thicker straps, ensuring more stable performance with the use of hot runner systems.

2.Higher-Quality Materials: We use high-quality materials that result in outstanding data for our cable ties.

3.Strict Quality Control: Our stringent quality control standards ensure that only high-quality cable ties are shipped, providing sustainable and stable supply to meet your needs.

4.More Material and Type Options: We offer a wide range of materials and types to cover various markets and applications.

5.Comprehensive After-Sales Service: Our team is dedicated to addressing your inquiries and providing solutions, ensuring you have all the information you need.