How to Choose Corrosion-Resistant Nylon Frame Fixing Industrial

Choosing the right corrosion-resistant nylon frame fastening solution is more than just a simple purchase; it's a critical investment in long-term operational stability. For industrial procurement professionals, the answer is simple: selecting the best nylon frame anchors requires a deep understanding of your specific environmental chemicals, mechanical load requirements, and substrate materials. This means going beyond generic options and choosing specialized, chemically inert polymers, such as high-quality polyamide-based anchors.

Standard metal fasteners—galvanized steel, stainless steel, and even some grades of 304 stainless steel—are susceptible to chlorides, acids, alkalis, and consistently damp environments. The result? Embrittlement, galling, and catastrophic loss of clamping force. I've witnessed firsthand so-called "stainless steel" anchors exhibiting pitting and cracking in salt spray environments, turning what were once secure frame fastenings into safety hazards. Data confirms this: research from materials associations shows that corrosion-related failures in auxiliary equipment account for nearly 30% of unplanned maintenance events in corrosive environments. The solution isn't to fight chemical corrosion with metal, but to circumvent it entirely by utilizing advanced engineering plastics.

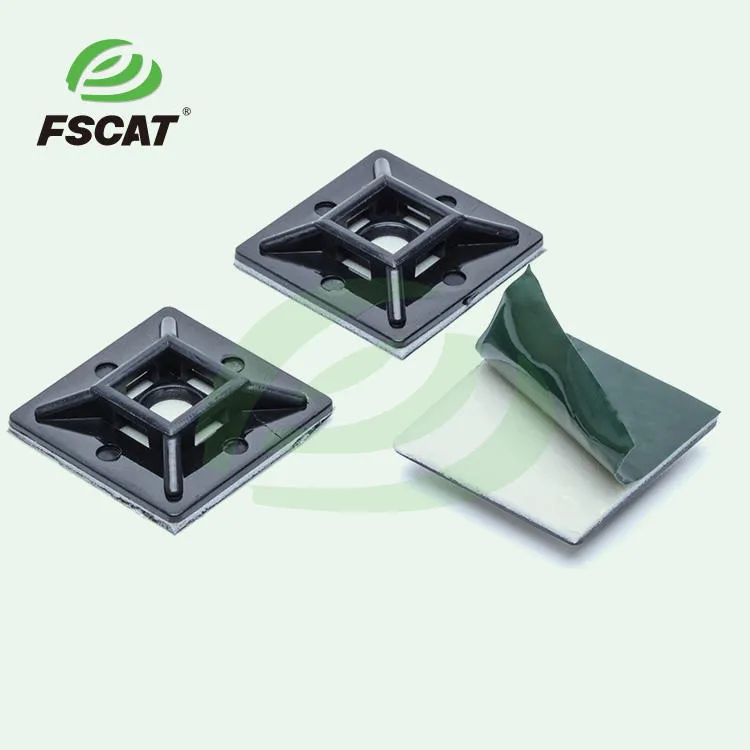

Fscat's nylon frame fastening product line often includes seemingly subtle but crucial design improvements: for example, radial ribs enhance torsional strength in masonry structures; streamlined drive heads prevent breakage from impact wrench forces; and color coding facilitates quick size identification for busy technicians. It's this attention to real-world user needs that sets Fscat apart.

Their versatility is impressive. In food-grade bottling plants, using Fscat non-metallic anchors eliminates the risk of rust contamination and complies with stringent HACCP protocols. On telecommunications tower structures, their UV resistance and electrical insulation properties protect both infrastructure and personnel. In a chemical laboratory, using these anchors to secure fume hood frames means no surprises during the next safety inspection. It's about comprehensive protection and peace of mind.

leading brands like Fscat don't just sell products; they solve problems. If your project involves unique chemical mixtures, unusual load conditions, or challenging substrates, contact their technical team. They can often customize material formulations or modify designs to provide tailored fastening solutions, transforming potential failure points into the most reliable links. This collaborative approach is what distinguishes a one-off transaction from a value-driven partnership.Ready to eliminate corrosion failures in your frame installations? Don't risk using generic solutions. Explore Fscat's range of engineered corrosion-resistant nylon anchors and industrial plastic fasteners. Visit their plastic anchor solutions page today to access technical data sheets, chemical resistance charts, and contact their engineering support team to select the perfect anchor for your next project.

SEO Keywords

plastic anchor

nylon frame anchor

corrosion-resistant fixing

industrial nylon anchor

heavy-duty plastic anchor