The Locking Machanism of Cable Ties

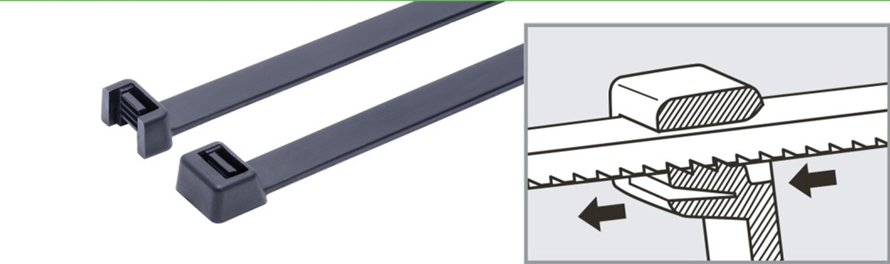

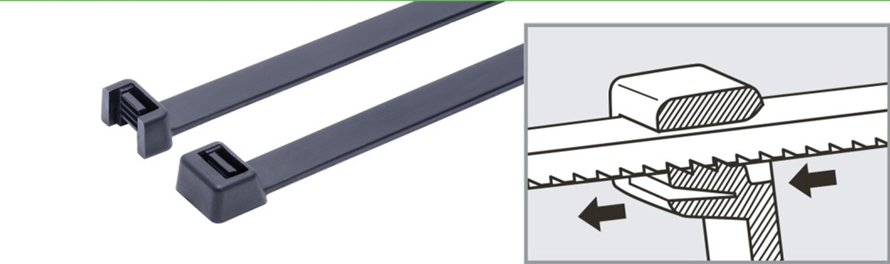

This technology is used in 90% of all polyamide (PA)cable ties applied by Tolerance. in order to cover a varietyof applications, thereare diferent variants of this system, for example: releasable verslons and in-line versions, These are one-piece cable ties, that thepawl is moulded as an integral part of the cable tie, thereby building in inherent strenaths.

Locking technology

Positive locking is achieved by engaging the pawl with the strap serrations. This allows the cable tie to perform to the publishedminimum tensile strength, that is the load that the cable tie can hold under application,

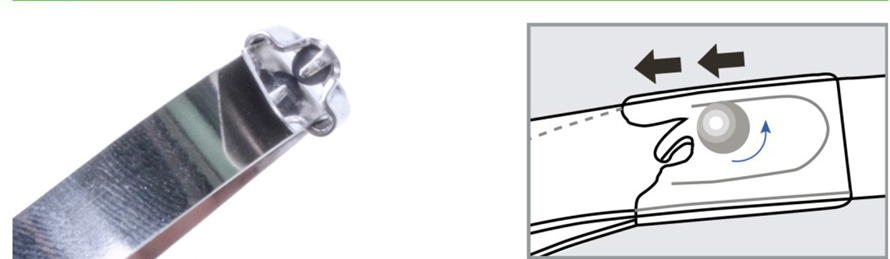

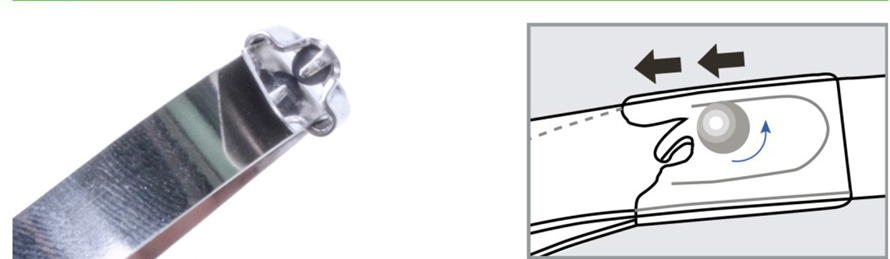

The Locking Machanism of Ball LockType Stainless Steel Cable Ties

Made of stainless steel grades 304 or 316, the MlG range of cable ties has no serations on the strap and are threaded parallel throughthe head, glding undera metal bal-bearing locking mechanism.By using the GlT-705 appication toolthe cable tie is tensioned andthe strap cut to a flush finish.

Locking technology

The strap is locked into the head by means of the smalbal-bearing.The ball locks into the smal end of thewedged shapedhousing, forming a positive locking with the strap.

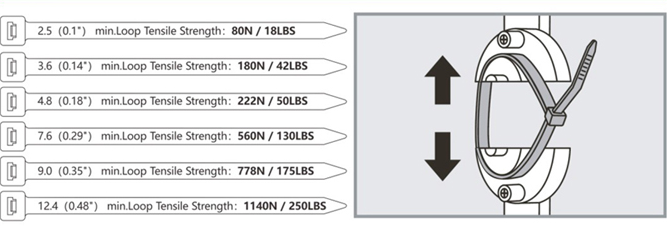

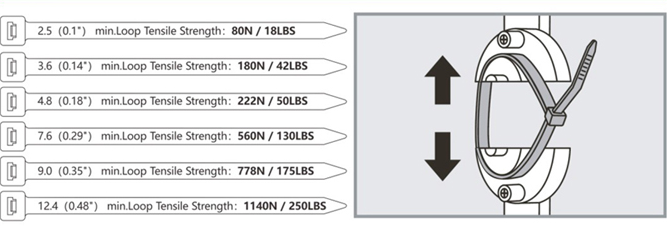

Determination of Minimum Tensile Strength

The minimum tensile strength is a critical selection criterion for cable ties. it expresses how much loada cable tie can bear. This minimum tensile strenath is determined in accordance with the MilitarySpecificationand Standards of the UsA. Test conditions are precisely defined in MlL-S-23190E

- Conditioning of the test pieces

- Construction of the test apparatus

- Application of the tie on a split test probe

- Test speed

The test procedure to determine minimum tensile strength

The cable tie is fixed onto a split mandrel test probe with the suitable cable tie application tool

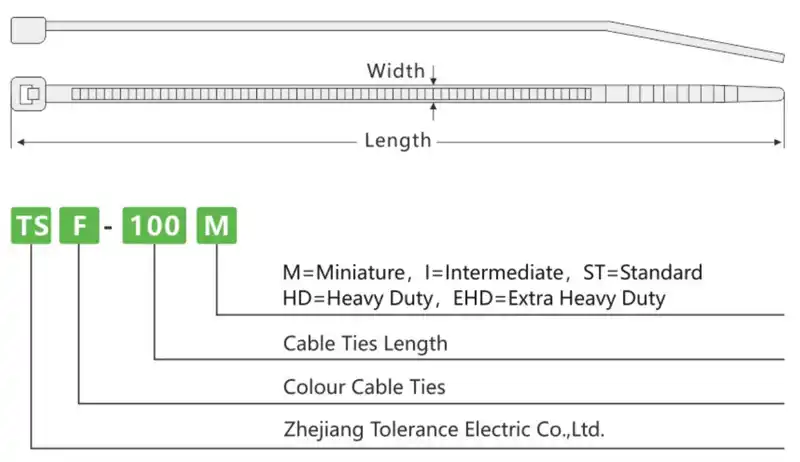

TSF-100M

TSF-100M TSF-200M

TSF-200M 100/250 pcs/bags

100/250 pcs/bags