Do Cable Ties Need to Be Replaced Regularly?

Cable ties, also known as zip ties, are essential fastening tools used in various industries, from electrical wiring to automotive and construction. However, a common question arises: Do cable ties need to be replaced regularly? The answer depends on the material, environment, and application.

I. Nylon Cable Ties: When Should They Be Replaced?

Nylon cable ties are the most widely used due to their affordability, flexibility, and ease of use. However, they are not indestructible and may require replacement under certain conditions.

Factors That Affect Nylon Cable Tie Lifespan:

UV Exposure: Standard nylon ties degrade when exposed to sunlight. If used outdoors, UV-resistant cable ties are recommended.

Temperature Extremes: Nylon becomes brittle in extreme cold and weakens in high heat (above 185°F/85°C).

Chemical Exposure: Harsh chemicals, oils, and solvents can weaken nylon over time.

Mechanical Stress: Constant vibration or tension can cause wear and eventual failure.

When to Replace Nylon Cable Ties?

If they appear brittle, discolored, or cracked.

If the locking mechanism no longer holds securely.

After prolonged exposure to harsh environments (e.g., outdoor or industrial settings).

For long-term applications, consider heavy-duty or weather-resistant nylon ties to extend lifespan.

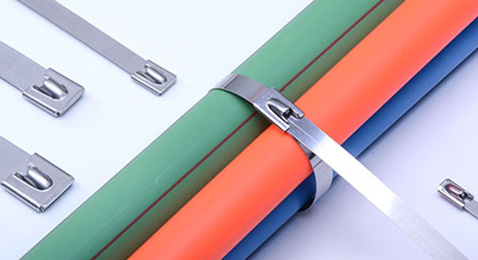

II. Stainless Steel Cable Ties: Do They Last Forever?

Stainless steel cable ties are known for their superior strength and resistance to extreme conditions. However, they are not always a "set-and-forget" solution.

Factors Affecting Stainless Steel Cable Ties:

Corrosion Resistance: While stainless steel resists rust, low-quality variants or exposure to saltwater can still cause corrosion.

Temperature Resistance: They perform well in high-heat environments (up to 1000°F/540°C), making them ideal for industrial uses.

Abrasion & Wear: Metal ties can wear down if subjected to constant friction.

When to Replace Stainless Steel Cable Ties?

If visible rust or corrosion appears (especially in marine environments).

If the locking mechanism is damaged or no longer secures properly.

If exposed to extreme mechanical stress that could deform the metal.

For critical applications (e.g., aerospace, marine, or high-temperature industries), high-grade stainless steel ties (316 stainless steel) are the best choice.

III. How Often Should You Inspect Cable Ties?

Regular inspection ensures safety and reliability. Here’s a quick guideline:

| Environment | Inspection Frequency |

| Indoor, mild conditions | Every 2–5 years |

| Outdoor, UV exposure | Every 1–2 years |

| High-temperature areas | Annually |

| Industrial/harsh conditions | Every 6–12 months |

IV. Choosing the Right Cable Tie for Longevity

To minimize frequent replacements:

For general use: UV-resistant nylon ties.

For extreme heat/cold: High-temperature nylon or stainless steel.

For corrosive environments:316 stainless steel ties.

For heavy-duty applications:Reinforced or metal-banded ties.

Conclusion:

Nylon cable ties age over time and need to be replaced periodically, while stainless steel cable ties offer a more durable solution in harsh conditions. FSCAT offers a full range of high-quality cable ties. Contact us for professional recommendations to help you get the best performance and safety.