What Should You Do to Maintain Cable Clamps and Prevent Common Failures Over Time?

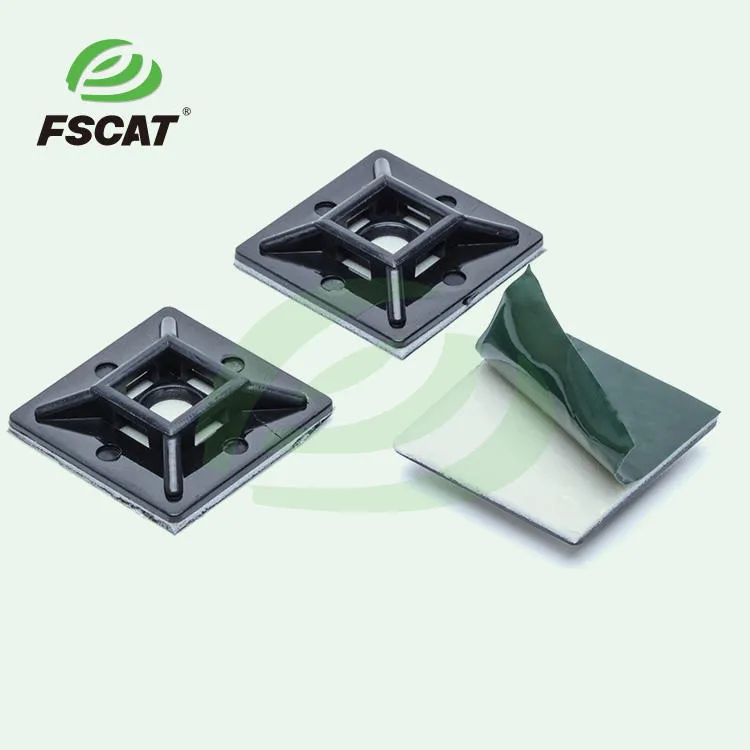

Cable Clamps keep cables organized and secure in industrial setups, automotive systems, or everyday electrical projects. Yet many users only focus on proper installation and overlook post-installation care—often leading to unexpected issues. This article answers how to maintain these clamps effectively to extend their service life and avoid costly failures.

Why Is Maintaining Cable Clamps Necessary?

Maintaining clamps directly impacts the safety and reliability of your cable setups. Here are two core reasons:

To Keep Cables Stable and Secure

Cable Clamps are designed to hold cables in place, preventing movement from vibration, temperature shifts, or accidental bumps. Over time, even well-installed clamps can loosen—especially in high-vibration areas like machinery or vehicles. A loose clamp lets cables shift, damaging insulation, disrupting connections, or creating safety risks. Regular maintenance ensures clamps stay tight enough to do their core job: securing cables consistently.

To Slow Down Environmental Wear

Cable Clamps face constant environmental stressors—outdoor UV rays, indoor humidity, or industrial chemicals. These break down materials gradually: plastic clamps may become brittle under UV exposure, while metal parts can rust in damp spaces. Maintenance spots early wear signs before clamps fail completely.

What Are Common Maintenance Mistakes to Avoid?

Even with good intentions, wrong habits can harm clamps. Here are two frequent errors:

Ignoring Environment-Specific Needs

A one-size-fits-all maintenance routine doesn’t work. For example, clamps in high-humidity areas need more frequent rust/material checks than those in dry offices. Overlooking these needs means missing early failure warnings.

Over-Tightening or Leaving Clamps Too Loose

When adjusting clamps, two mistakes are common: over-tightening (cracks plastic clamps or damages cable insulation) and under-tightening (fails to secure cables). Fasten clamps just enough to keep cables stable—no extra force—to balance security and protection.

What Are Simple, Effective Maintenance Steps?

You don't need special tools for maintenance. These three easy steps work for most setups:

Schedule Regular Visual Inspections

Set a regular interval—3–6 months, depending on the environment—to check clamps visually. Look for cracks, discoloration, rust on metal parts, or cables that shift when gently touched. Catching issues early makes fixes or replacements faster and cheaper.

Clean Clamps Gently When Needed

Dirt, dust, or chemical residues build up on clamps over time—especially in industrial or outdoor settings. These speed up wear. Clean clamps with a soft cloth and mild soap (avoid harsh chemicals that damage materials) to keep them in good shape.

Replace Damaged Clamps Promptly

If an inspection finds a cracked, rusted, or brittle clamp, replace it right away. Using a damaged clamp won’t secure cables reliably. Choose a replacement matching the original’s size and material to ensure it fits the cables and environment.

Conclusion

Maintaining Cable Clamps is simple but critical for safe, functional cable systems. Avoid common mistakes, follow basic inspection steps, and address wear early to extend clamp life and prevent unexpected failures.

If you’re looking for clamps built to withstand different environments (and easier to maintain), or want to learn how our clamps meet specific needs, visit our product page for detailed specs and options.