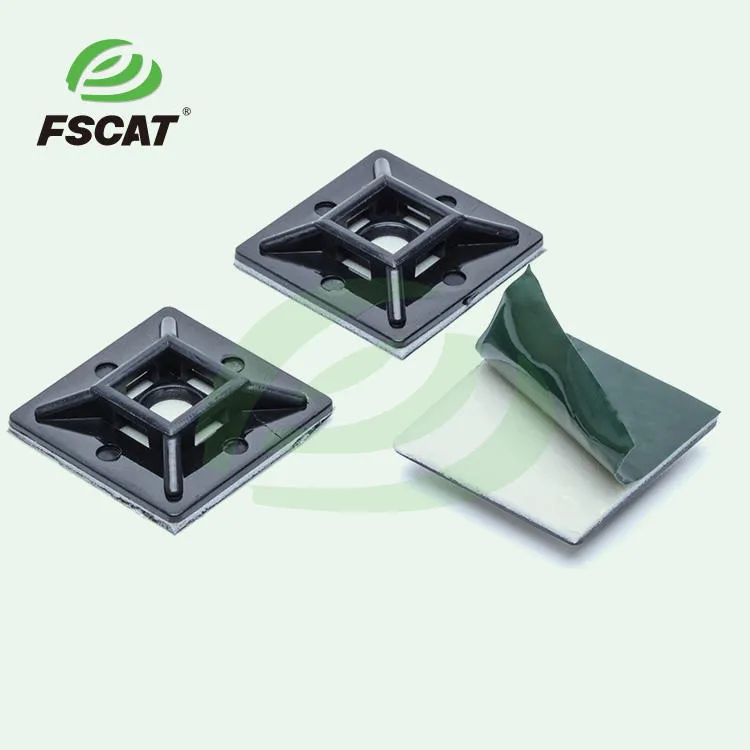

What are Applications of Stainless Steel Zip Ties?

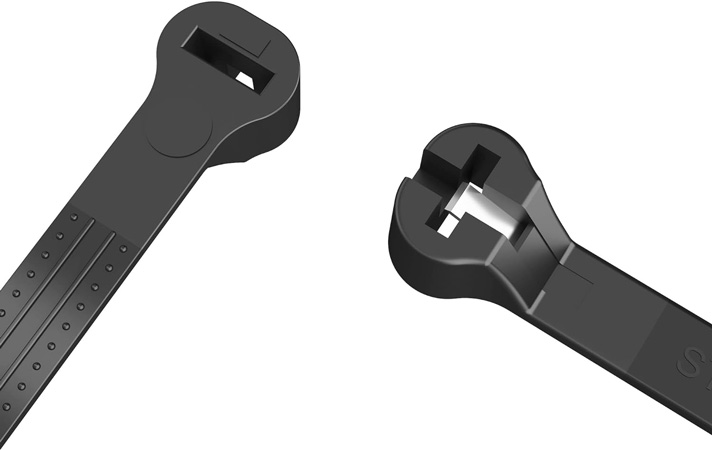

Stainless steel barb nylon zip ties are revolutionizing fastening solutions with their added durability and strength. Here's a streamlined breakdown of their diverse applications:

1. Strong Fastening:

These ties excel in heavy-duty tasks, securely holding industrial equipment and reinforcing structures.In the realm of cable management solutions, Barb Nylon cable ties emerge as versatile fastening tools with an extensive array of applications.

2. Construction Support:

In the construction industry, Barb Nylon cable ties play a pivotal role in securing and bundling materials. Their ability to endure outdoor and harsh conditions makes them an ideal choice for construction sites, where reliability is paramount.

3. Automotive Maintenance:

The automotive sector benefits immensely from the strength and durability of Barb Nylon cable ties. These ties find their place in securing wiring harnesses and cables within vehicles, providing a reliable fastening solution that withstands the challenging conditions of the automotive environment.

4. Outdoor and Harsh Environments:

Barb Nylon cable ties are built to withstand the elements, making them the ideal choice for outdoor applications. Their resilience in the face of weather elements positions them as reliable fasteners for outdoor settings, such as camping, hiking, and other outdoor adventures.

5.Safety and Emergency:

The HVAC industry benefits from the robust nature of Barb Nylon cable ties, using them to secure ducts, cables, and components. Their durability is a significant advantage in the demanding conditions of HVAC installations.

6. DIY Projects:

Barb Nylon cable ties stand out as the go-to choice for seamless cable organization. Whether you're dealing with a complex network of wires in a data center or a DIY project at home, these cable ties offer a robust solution for bundling and tidying up cables, ensuring a clutter-free and organized environment.

7. HVAC Systems Securely Managed:

The HVAC industry benefits from the robust nature of Barb Nylon cable ties, using them to secure ducts, cables, and components. Their durability is a significant advantage in the demanding conditions of HVAC installations.

8. Agriculture Finds a Reliable Partner:

Agricultural settings leverage the versatility of Barb Nylon cable ties for bundling and securing items. Their resistance to environmental factors makes them a reliable choice for various agricultural applications.

9. Networking and Data Centers:

Efficient cable management is critical in networking and data centers. Barb Nylon cable ties play a crucial role in organizing and securing network cables, contributing to the creation of a neat and efficient data infrastructure.

In conclusion, the applications of Barb Nylon cable ties are diverse and expansive, catering to the needs of different industries and scenarios. From cable organization to automotive, construction, DIY projects, outdoor adventures, logistics, HVAC, agriculture, and networking – these cable ties prove to be reliable, durable, and versatile companions in various settings. Choose Barb Nylon cable ties for a cable management solution that not only meets but exceeds expectations.