The importance and characteristics of injection molding machines in the production process of nylon cable ties

Introduction to Nylon Cable Tie Production

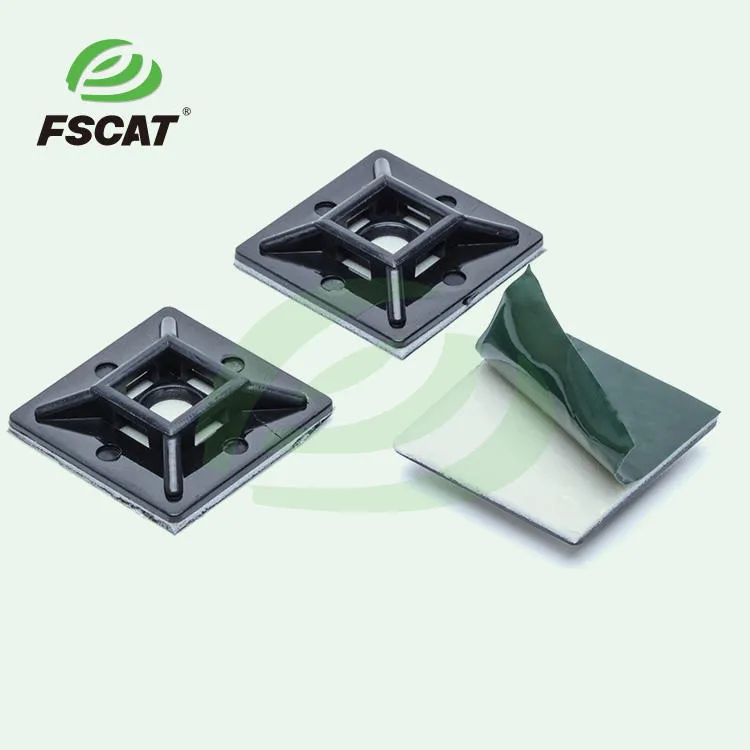

The production process of nylon cable ties is a sophisticated and precise operation, heavily reliant on the utilization of injection molding machines. These machines are pivotal in shaping the nylon pellets into the desired tie forms. Let's delve deeper into this fascinating journey of production and explore the critical role of injection molding machines.The production process of nylon cable ties is a sophisticated and precise operation, heavily reliant on the utilization of injection molding machines. These machines are pivotal in shaping the nylon pellets into the desired tie forms. Let's delve deeper into this fascinating journey of production and explore the critical role of injection molding machines.

In the realm of nylon cable tie production, injection molding machines play a paramount role. They are responsible for melting the nylon pellets and injecting them into molds to create the intricate tie shapes. This process demands meticulous control and advanced technology to ensure the quality and functionality of the end products.

One of the standout features of injection molding machines is their exceptional efficiency and adaptability. They boast the capability to swiftly respond to market demands and adapt production plans accordingly. Whether it involves large-scale manufacturing or customized orders, injection molding machines excel in meeting diverse requirements.

Quality assurance and continuous improvement are integral aspects of the production process facilitated by injection molding machines. Through stringent quality control measures and ongoing enhancements, these machines ensure that the produced nylon cable ties adhere to the highest standards. Continuous refinement of production processes and technological advancements further elevate the quality and performance of the products.

In conclusion, injection molding machines serve as indispensable assets in the production of nylon cable ties. Their precision engineering and efficient production capabilities provide a solid foundation for the quality and dependability of nylon cable ties. Opting for nylon cable ties means embracing the excellence of injection molding machines, offering optimal binding solutions for your engineering projects.